The Industry Leader of Precision

Cold Rolled & Cold Drawn Metal Profiles

ISO 9001 Certified

UEI: HVHDQ2UJQXJ7 | CAGE: 13A10

Home » What We’ve Made » Cold Rolled Steel Turbine Seal

The Industry Leader of Precision

Cold Rolled & Cold Drawn Metal Profiles

ISO 9001 Certified

UEI: HVHDQ2UJQXJ7 | CAGE: 13A10

Home » What We’ve Made » Cold Rolled Steel Turbine Seal

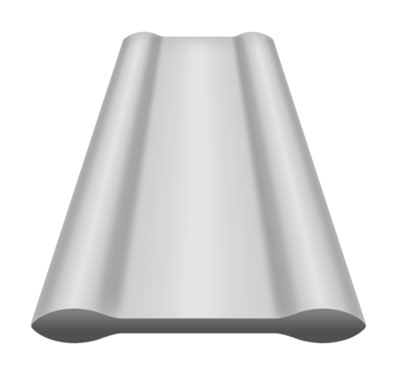

A customer in the power generation industry approached Rathbone Precision Metals, Inc. looking for an economical alternative for seals used in a gas turbine application. This project took advantage of our unique ability to work with high temperature, high strength alloys to deliver profiles with precise dimensional accuracy. Formed from L605 Alloy Steel to withstand exposure to the extreme temperatures found in gas turbine environments, we manufacture this .498″ wide x .060″ thick seal profile, with a thin web of only .028″ across the width and a 125 Ra finish. Rathbone delivers these profiles in 36″ cut lengths to a +0″/-.060″ tolerance.

These cold rolled steel profiles offer the same precision achieved by machining, but without the scrap, which substantially reduced material costs and provided a significant savings for the customer.

To learn more about this profile as well as others, or how cold drawn and cold rolled profiles could benefit your application, please contact Rathbone today.

| Label | Content |

|---|---|

| Product Application | This turbine seal is used in a gas turbine application. |

| Capabilities Applied/Processes | Roll & Die Design and Manufacturing Our Unique Capabilities Allow us to Cold Work High Temperature Alloys and Hold Thin Web Across the Width of the profile. |

| Customer Benefits: |

|

| Overall Profile Dimensions | Width: .498″ |

| Tolerances | Width: ±.005″ |

| Material Used | L605 Alloy Per AMS 5537 |

| Max Material Finish | 125 Ra |

| Estimated Profile Weight | .0697 lbs per ft |

| Industry for Use | Power Generation |

| Standards Met | Per Customer Supplied Specifications |

| Product Description | Turbine Seal |