The Industry Leader of Precision

Cold Rolled & Cold Drawn Metal Profiles

ISO 9001 Certified

UEI: HVHDQ2UJQXJ7 | CAGE: 13A10

Home » Industries We Serve

The Industry Leader of Precision

Cold Rolled & Cold Drawn Metal Profiles

ISO 9001 Certified

UEI: HVHDQ2UJQXJ7 | CAGE: 13A10

Home » Industries We Serve

Detailed below are just a few of the many Industries that Rathbone has proudly served since it’s inception in 1905.

The accuracy and precision offered by a cold drawn and cold rolled shaped profile are especially valuable in the medical industry.

Surgical tools and medical implants require some of the tightest tolerances in industry. Our cold working methods are compatible with many highly specialized metal alloys often used in this sector.

Whether you use a 17-4 or 304 Stainless, a cold worked profile will provide you with a consistent dimensional near net shape.

The aerospace industry has stringent quality requirements, for this reason companies opt to utilize a cold drawn and cold rolled profile.

With increased stresses placed on aerospace components, cold drawn profiles are an excellent starting material to produce your parts. Cold worked profiles have improved grain alignment which improves impact and fatigue resistance.

The dimensional bar-to-bar consistency of a cold drawn profile is exactly what the aerospace industry requires.

Rathbone proudly produces profiles used in various applications for the defense of our nation.

While Rathbone began by making components for the clock industry in 1905, Rathbone transitioned around 1940 and commenced producing profiles for various applications in the defense industry. It was due to the timesaving benefits of our cold worked profiles, that US manufactures were able to increase output and thus meet the needs of the time.

Please see our forms page to read an interesting article – The “Secret Weapon” that helped to win the battle of production.

Energy is a necessity and the equipment used to produce energy must be able to work in all environmental conditions. Cold drawn and cold rolled profiles also provide smooth surfaces which may be acceptable as is.

For extreme environments, a smoother surface finish better facilitates the formation of stable and protective oxide layers. These oxide layers help prevent further corrosion caused by the aggressive environment of energy production.

Work hardening through cold working metal also provides more resistance to extreme pressures often experienced in the production of energy. The durability and dimensional consistency of a cold worked profile complements these applications.

Water distribution is critical to any society and Rathbone’s profiles support these efforts. Ductile Iron pipes can be connected using a restraining gasket, which has “metal teeth” molded into the rubber gasket that aid in the delivery of sweet water/drinking water.

The required sharpness of the “metal teeth” is a critical component of these molded gaskets that bite into the pipe and form a tight but flexible connection. The expertise of the Rathbone Team consistently provides profiles with the “tooth sharpness” this industry demands.

As an added value, Rathbone offers cut-to-length pieces, providing ready to use parts to our customers.

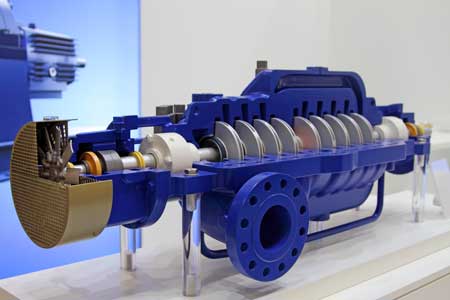

Whether it is a steam generator or land-based power generation unit, the cold work process is the ideal process to form shapes for power generation equipment.

The cold rolling process provides a 32 Ra or better smooth work surface that is critical to air flow performance. As an added benefit, work hardening through the cold work process improves the mechanical properties of the metal adding stability and rigidity to the part.

Cold rolling is the ideal process that provides high quality reliable parts to this industry.

One of the benefits of automation and processing equipment is the consistency and reliability it delivers. A cold worked profile provides our customers with the ability to pass this benefit on to their customers.

One advantage of utilizing a Rathbone profile for your application is lot-to-lot repeatability. Rathbone’s cold worked profiles provide a uniform and consistent part that you can rely on.

Precision cold drawn and cold rolled profiles are a valuable resource for the automation and processing equipment industry.